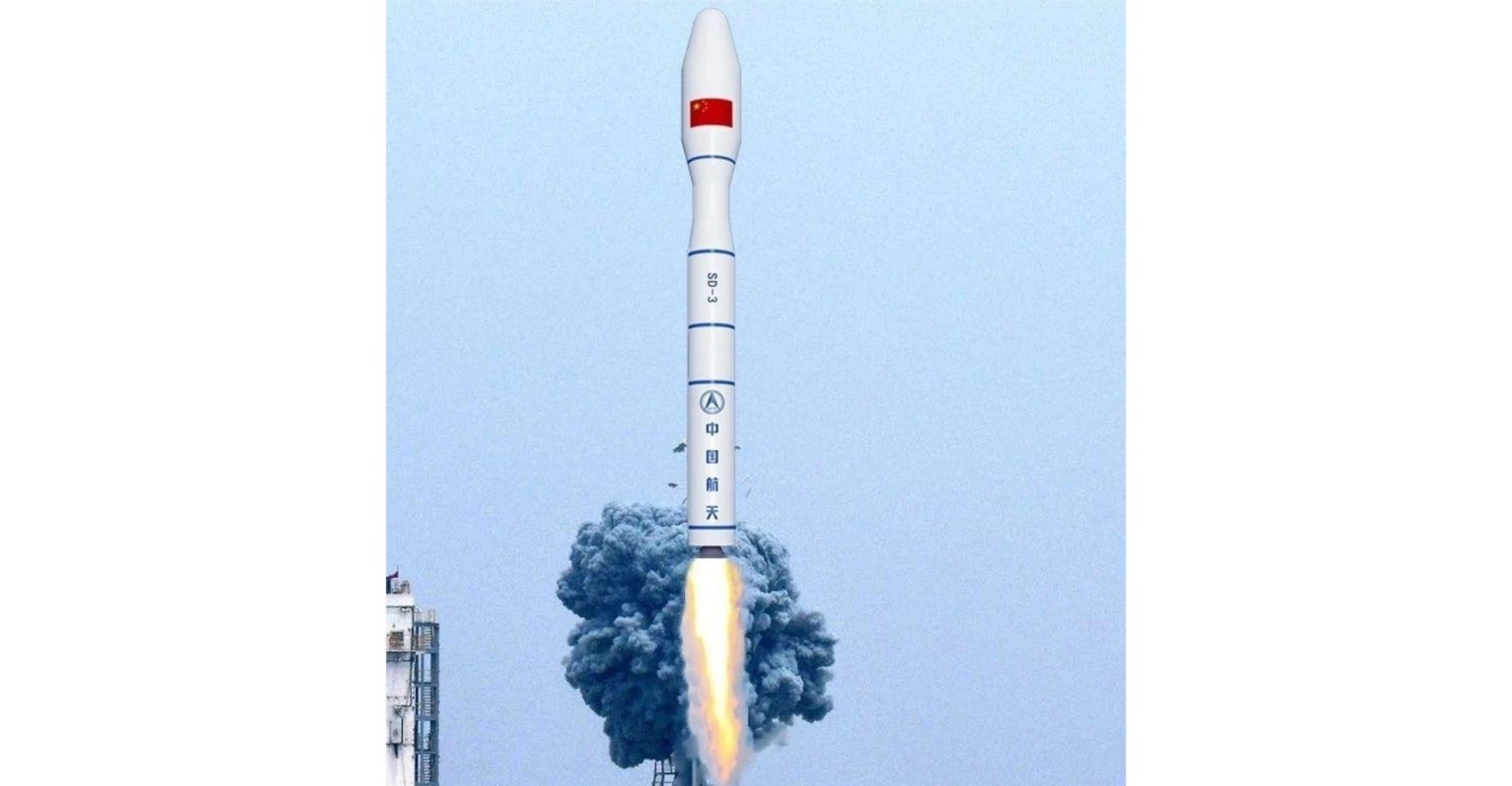

China’s Jielong-3 Carrier Rocket Enters First Flight Test Stage

On August 9, the four-stage solid-propellant carrier rocket, the Jielong-3, which was developed by China Rocket, has successfully completed its static and separation test of fairing.

On August 9, the four-stage solid-propellant carrier rocket, the Jielong-3, which was developed by China Rocket Co., Ltd. of the China Academy of Launch Vehicle Technology, has successfully completed its static and separation test of fairing. The success marks the completion of the large-scale ground test in the engineering stage of Jielong-3. The rocket is now to be transferred to the first flight test stage.

During the rocket's ascent into space, the fairing protects the payload, such as a satellite, from extreme environmental conditions such as heat, humidity, sound and vibrations. The fairing is a "home" for the satellite which ensures its safety. This requires the fairing to remain stable when playing the protective role and then break away smoothly after completing its "protection task", so it needs an extra rigorous testing process.

The fairing of the Jielong-3 is the fairing with the largest enveloping space used by solid rockets in China at present. Static tests of fairing materials mainly verify the structural integrity of the components, while verifying the design scheme, reliability of materials, dimensions, connection modes and other elements of main load-bearing components. The tests also allow the calculations of the fairing separation of the Jielong-3.

SEE ALSO: China Launches CERES-1 Y3 Carrier Rocket With Three Satellites

Gao Lijun, head of the fairing separation test of Jielong-3, introduced that in order to ensure that satellite protection is in place while docking with satellites, in the fairing separation test, the team maximized the envelope of collision danger points for the simulated satellite. The fairing was designed with consideration towards environmental protection for the satellite. All of the separation devices have adopted mature products verified by the Long March Carrier Rockets, which would not affect the satellite in the separation process.

The main structure of the fairing is made of a honeycomb core sandwich composite which quickly attenuates noise and impact while providing a reliable mechanical environment for the satellites. In addition, in the fairing design itself, there are special environmental protection equipments and environmental monitoring interfaces to ensure that it can be monitored at any time and meet the temperature, humidity and cleanliness requirements of satellites.