Unmanned Forklift Robotics Company Tusk Raises Hundreds of Millions of Yuan

Tusk, an unmanned forklift robotics company, has received three rounds of financing totaling several hundred million yuan, following investment by Engage Capital, ZhenFund and 01VC.

36Kr reported on September 5 that Tusk, an unmanned forklift robotics company, has received three rounds of financing totaling several hundred million yuan, following investment by Engage Capital, ZhenFund and 01VC. The funds will be mainly used for product development, team building and marketing.

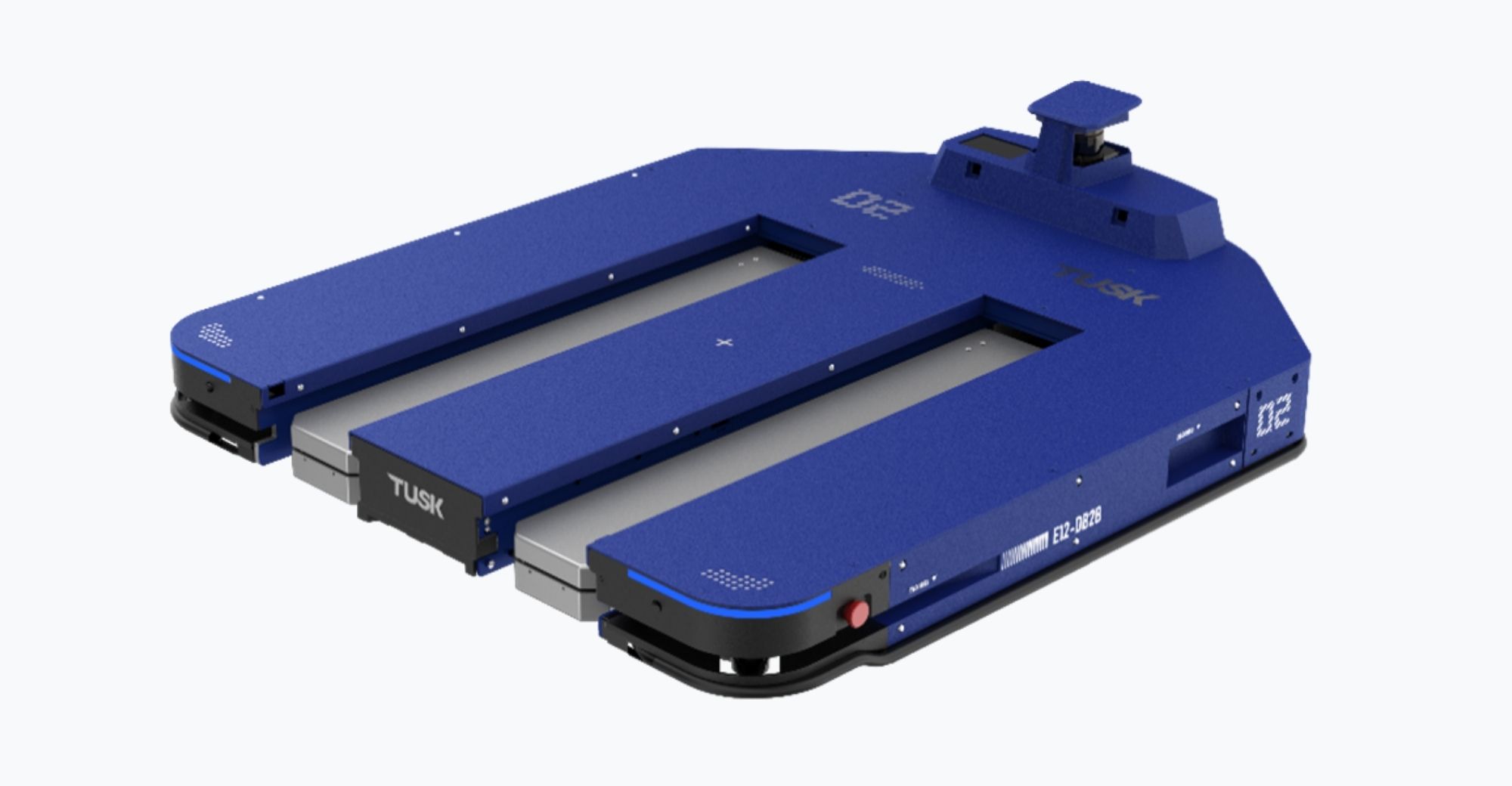

Tusk was founded in 2021, and is located in Foshan, Guangdong Province. Its unmanned forklifts are different from products available on the market, as they integrate automated guided vehicle (AGV) robotics with unmanned forklifts functions. As their product definition is completely different from traditional forklifts, Tusk forklifts have an overall height of no more than 150 mm, and are therefore called stealth pallet robots.

Tusk has given its unmanned forklifts a thin and light chassis form, allowing lidar to be carried on the chassis as well. It thus improves the obstacle avoidance of previous modified forklifts, realizes 360-degree laser obstacle avoidance, and is able to detect objects in its path as low as 4cm in stereo vision.

It is also different from traditional submerged top-lift (kiva-like) robots in that it can carry pallets directly without additional carriers. This design has even more advantages in terms of the robot's stability. Cargo can be carried directly on the robot, rather than by the fork arms, and the lower center of gravity and larger contact area make for more stable cargo handling.

SEE ALSO: Cloud-Native RPA Manufacturer Uniner Technology Secures Round-A Financing

Such forklifts are also capable of in-situ rotation and omnidirectional movement. They have no turning radius and can pass in aisles as narrow as 1.3 meters. In terms of operating efficiency, Tusk's unmanned forklifts can achieve high-speed operation of 1.5m/s, and the operating demand is smaller than the manual working space, which also improves operating efficiency to a certain extent.

On one hand, Tusk adopts a modular approach to make its hardware equipment more standardized in form. In terms of software, Tusk designs a low-code system to allow users to achieve rapid deployment by dragging and dropping the build diagram, shortening project implementation cycles to less than one week.